Predictable bone augmentation

In the augmentation of bone defects, the final bone structure is an important success factor in order to achieve the highest esthetic standards. Positional stability and shape are of the highest priority for the selected bone augmentation material.

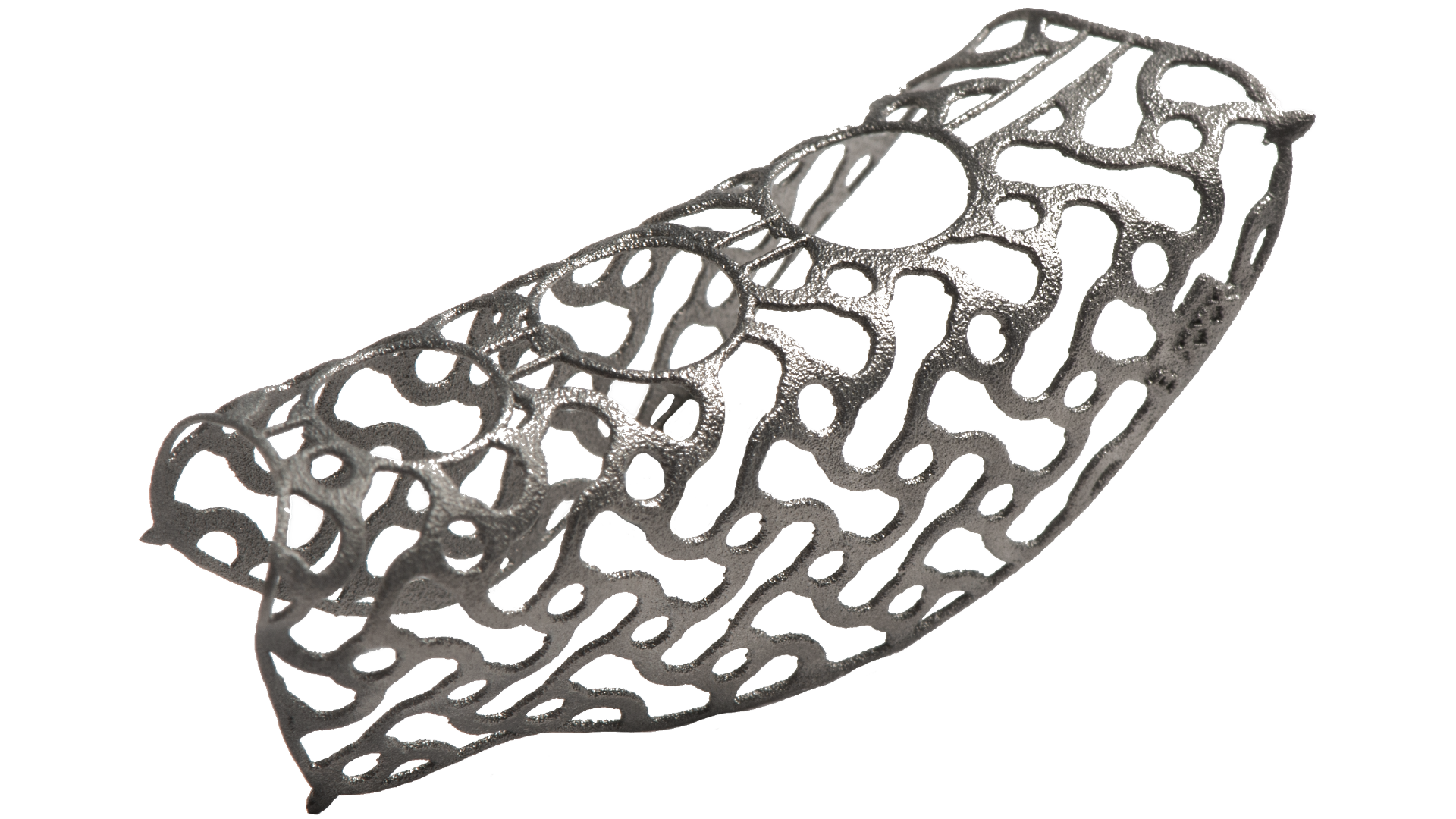

The individually shaped Yxoss CBR® titanium scaffold enable a stability and accuracy of fit of the previously planned augmentation volume that was unknown in augmentation procedures before. With the patented process for manufacturing individual patient solutions, ReOss® offers high-quality individual products for "customized bone regeneration".